News — Df96

CineStill Dev Days Part 2! - 6pm PST on Instagram Live, FRIDAY APRIL 3rd

Posted by CineStill on

Join us at the same time, same place - 6pm PST on Instagram Live, FRIDAY APRIL 3rd- for our second Cinestill Dev Day! This time, we'll be doing a live walk-through of the LAB-BOX 35mm Module, DF-96 Monobath, and will be processing a roll of BwXX. Live and on the air!

Read more →

Stay Home, Stay Safe, Shoot Film!

Posted by CineStill on

We want to let you know that we're still here. We're still operating. We may have to adapt, but we will not quit. CineStill's commitment is to deliver orders to our customers, while maintaining a safe environment for all of us. Fulfillment remains unaffected by Safer At Home because the government considers fulfillment an essential service. Some shipping carriers are running with reduced service levels, but we are still fulfilling all orders. Be sure to scroll down for some important updates...

Read more →

No Compromises - Df96 compared with popular traditional developers

Posted by CineStill on

Due to the long history of multiple bath processes being the only ones available, many may wonder, "What are the compromises with a monobath?" Well, we can tell you that it is not compromised quality with Df96. We are standing on the shoulders of giants, and the reason monobaths weren't popular before is most likely because of economies of scale and cost, in addition to shorter shelf life. In the past, there was more profit in just producing the large volume photochemicals for film to be processed en masse. After all, back then everyone had to process film to capture a photo. Now that craft film manufacturing is being tooled for smaller batches, lower volume products can be more viable. Small batch, on demand, chemical manufacturing works just like craft beer. Fresher product with more characteristics. Thus the modern monobath was born, formulated to be produced at a craft scale.

Df96 is very forgiving for all film speeds and different emulsion types. This is partially because of the advanced developing agents used. But also as chemical development self-completes, archival fixation takes over breaking down silver and allowing physical development to redeposit it in thin areas of the film, while diffusing the grain to be finer and smoother. As you can see in the samples below, it renders somewhere between the Ilfotec DDX grain structure and Kodak Professional HC-110 tonality.

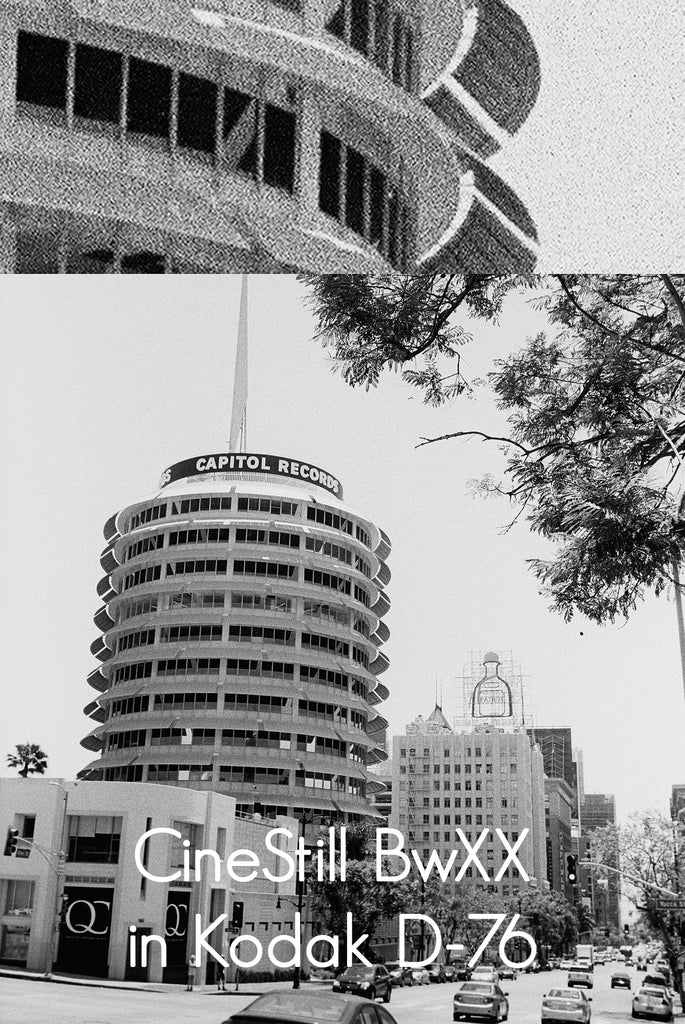

Detail crop of BwXX processed at ISO 250 in HC-110 liquid concentrate, Df96 monobath, and D-76 powder chemicals.

Detail crop of BwXX processed at ISO 250 in DD-X liquid concentrate, Df96 monobath, and ID-11 powder chemicals.

Df96 also works well with tabular grain films, like Tmax, but to fully eliminate residual color dyes in the emulsion we double the recommended processing time. This does not affect the image since all films complete development within the first 3 minutes. Below you can see the smoothness and crisp contrast Df96 pulls out of TMax100...

Read more →

Processing 16+ different B&W films with just one chemical! Df96

Posted by CineStill on

Out of all of the available processes we've had the pleasure of using, Df96 is possibly the most uniform and consistent with all emulsions. It's not only a single-step solution, it makes over processing virtually impossible. We decided to test processing over 16 different emulsions exposed at their box speed, in one bath, at the same time, at the same temperature. Df96 has terrific uniformity due to the simultaneous development and fixing of the silver, competing to reveal every detail, from the most subtle to extreme exposure.

Df96 monobath easily processes any standard black and white film at any room temperature. It is designed with traditional cubic-grain emulsions in mind, like BwXX, TriX and HP5. It also works well with tabular grain films containing color dye technology, like Tmax, but to eliminate residual dyes in the emulsion you should double the recommended processing time. High speed films like P3200 and Delta3200 can be processed between ISO 1000-1600 by the instructions on the label, or pushed to 3200 by adding 10°F (6°C)....

Read more →

Introducing: DF96 “DEVELOPER&FIX” SINGLE-STEP - B&W MONOBATH PROCESSING

Posted by CineStill on

Developing black and white film just got a whole lot simpler with the CineStill Df96 Monobath. The worries of too much development, dilution, time or agitation are gone. Stop bath? Fixer? Hardener? Gone the way of One-Hour-Photos and formaldehyde. Finally, foolproof at home film processing.

Many of the pitfalls and hazards of a multi-bath process are eliminated with this ready-to-use single-step solution, such as improper dilution, over-agitation, bubble marks, surge marks, etc. Over-processing is impossible, because the fixing action overtakes chemical development while aiding physical development, creating better image uniformity and finer grain negatives.

Monobath solutions were first proposed as far back as 1889, but only recently have the difficulties associated with their formulation been possible to overcome. The main problem has been the loss of emulsion speed that results when the exposed silver halide is dissolved by the fixation process, before development can take place. Our monobath is unlike home concoctions or old technology that failed years ago. Df96 uses a more effective processing technology (akin to D96 motion picture developer) that buffers fixing, and archival fixing agents that are more solvent and aid in breaking down the silver and redepositing it, to achieve crisp uniform grain and wide development latitude...